About company

MM1986 Engineering Co.,Ltd.

Selling leading brand air compressors from Japan, Europe and America

Air Compressor (air compressor), Air Dryer (air dryer), Air Quality (air quality improvement equipment), Spare part (air pump spare parts) and various services

Such as Installation, installation service, Preventive Maintenance, preventive maintenance service, Efficiency Test, measuring the efficiency of air compressors.

Ready to serve 24 hours

Products and services

Our Products

Air Compressor

Spare Part

Air Dryer

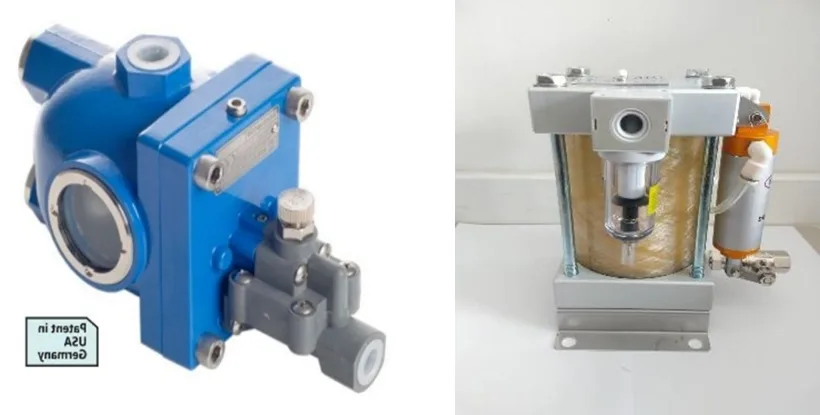

Auto Drain

Mainline Filter

Air Reciver Tank

Products and Services

Services of MM1986 Engineering

Maintenance

Monthly, yearly preventive inspection services with performance reports on customers' air compressors. and keep customer history With a team of engineers and expert technicians More than 18 years of work experience in preventive maintenance (PM), with details as follows:

- Air Compressor / air pump

- Air Dryer / Air drying machine

- Mainline Filter / Filtering equipment

- Air Receiver Tank / Air Receiver Tank

- Drain System/ Drain System

The goal of Preventive Maintenance is to maintain the efficiency of the air system. To be at the highest point and reduce the chance of a break down of the system. This is done to avoid problems with the user's production line system causing loss and to be able to control the production line to work according to schedule.

Over Haul

Over Haul service and repair of all models of air compressors. All brands by a team of experts and modern tools Work on time and get the quality as desired

Installation & Consut

(BS-M/Stainless/HDPE/PPR) Installation service, PM electrical system, DB/MDB electrical system, ready to give advice. The wind system is designed by experienced and expert engineers.

Inspection

Compressed Air System Audit

Measuring service, analyzing air consumption and energy consumption of compressed air systems

With modern equipment and technology We can measure And accurately analyze the air consumption and energy consumption of your compressed air system during each use period.